Mine Water Heat Recovery

Extract renewable heat from flooded mine workings to heat buildings. A pioneering low-carbon solution using Wales' industrial heritage for a sustainable future.

12-14°C

Year-Round TempLow Carbon

Heating SolutionWales First

Commercial Scheme

Mine Water Heat Recovery

Extract renewable heat from flooded mine workings to heat buildings. A pioneering low-carbon solution using Wales' industrial heritage for a sustainable future.

12-14°C

Year-Round TempLow Carbon

Heating SolutionWales First

Commercial Scheme

What is Mine Water Heat Recovery?

Abandoned coal mines across Wales and the UK are flooded with water that's naturally heated by the Earth's subsurface temperature. Mine water heat pump systems extract this thermal energy to provide low-carbon heating for homes, businesses, and communities.

What is Mine Water Heat Recovery?

Abandoned coal mines across Wales and the UK are flooded with water that's naturally heated by the Earth's subsurface temperature. Mine water heat pump systems extract this thermal energy to provide low-carbon heating for homes, businesses, and communities.

Why Choose Mine Water Heat?

Unlock the renewable energy beneath your feet

Constant Temperature

Mine water stays at 12-14°C year-round, providing a reliable heat source regardless of weather or season.

Zero Carbon Emissions

Replace fossil fuel heating with renewable geothermal energy. Significantly reduce your carbon footprint.

Mining Heritage

Transform Wales' industrial past into a sustainable future. Give abandoned mines a new purpose.

Scalable Solutions

Suitable for single buildings to entire district heating networks. Commercial and residential applications.

Reduced Energy Costs

Lower heating bills compared to traditional fossil fuels. Stable costs not tied to volatile gas prices.

Government Support

Aligned with Wales' Heat Strategy and net-zero targets. Potential funding and grant opportunities.

Why Choose Mine Water Heat?

Unlock the renewable energy beneath your feet

Constant Temperature

Mine water stays at 12-14°C year-round, providing a reliable heat source regardless of weather or season.

Zero Carbon Emissions

Replace fossil fuel heating with renewable geothermal energy. Significantly reduce your carbon footprint.

Mining Heritage

Transform Wales' industrial past into a sustainable future. Give abandoned mines a new purpose.

Scalable Solutions

Suitable for single buildings to entire district heating networks. Commercial and residential applications.

Reduced Energy Costs

Lower heating bills compared to traditional fossil fuels. Stable costs not tied to volatile gas prices.

Government Support

Aligned with Wales' Heat Strategy and net-zero targets. Potential funding and grant opportunities.

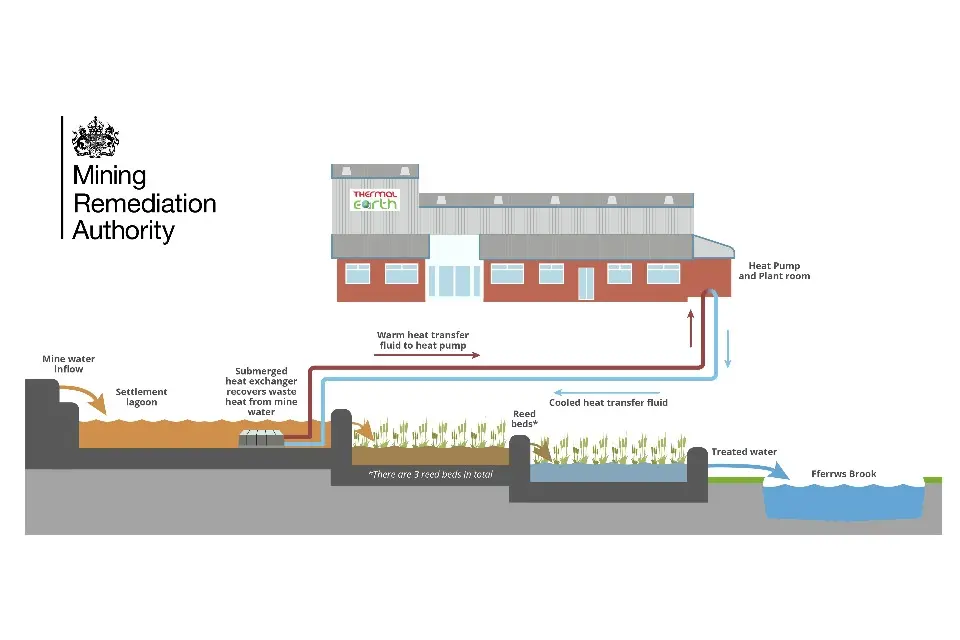

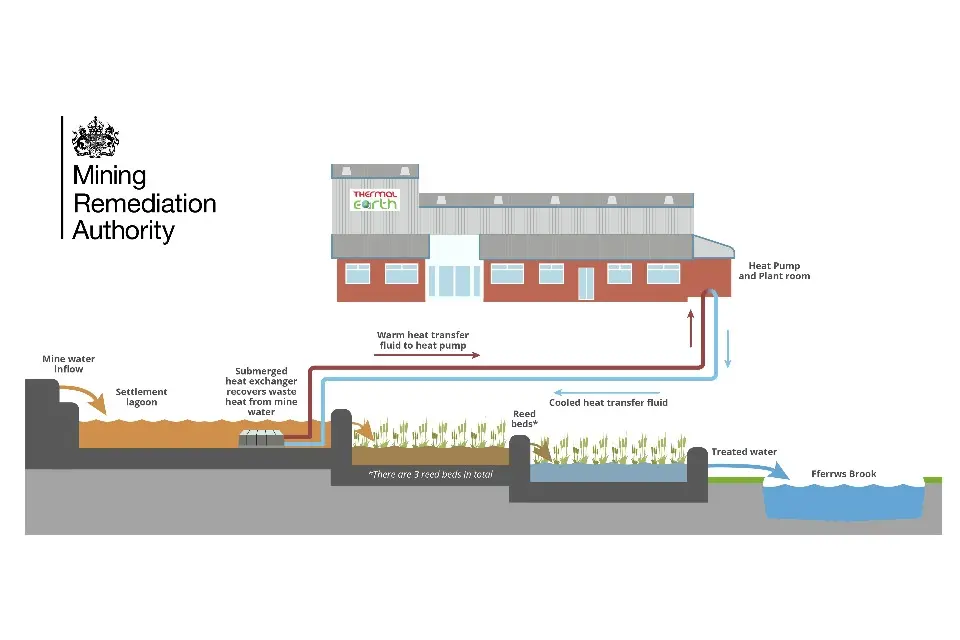

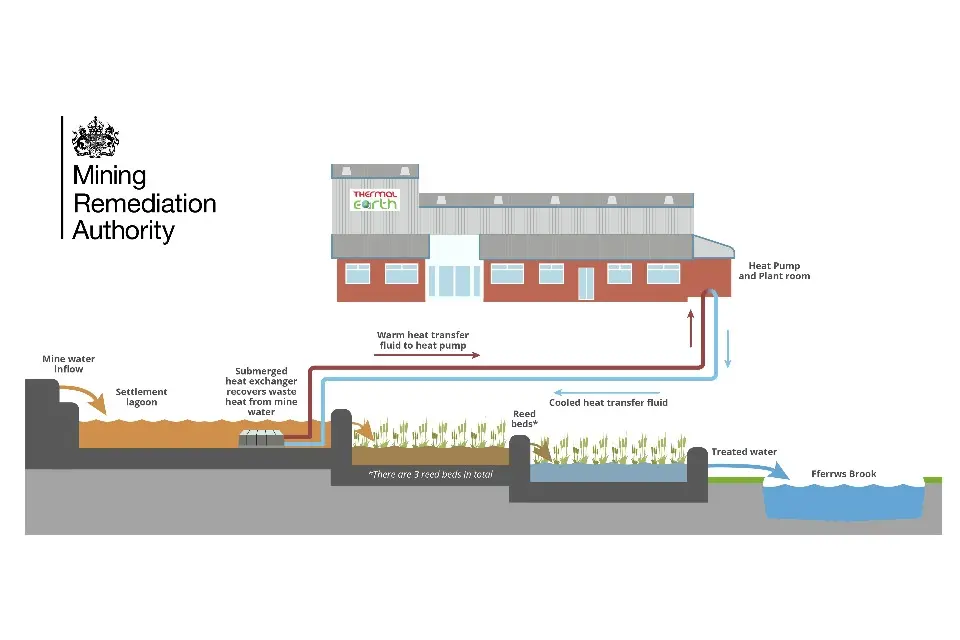

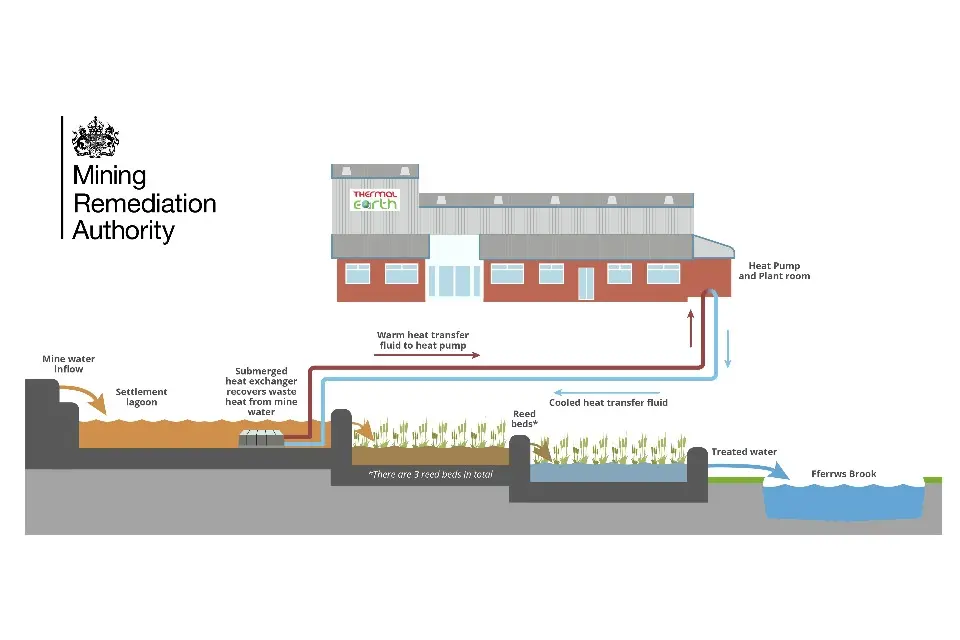

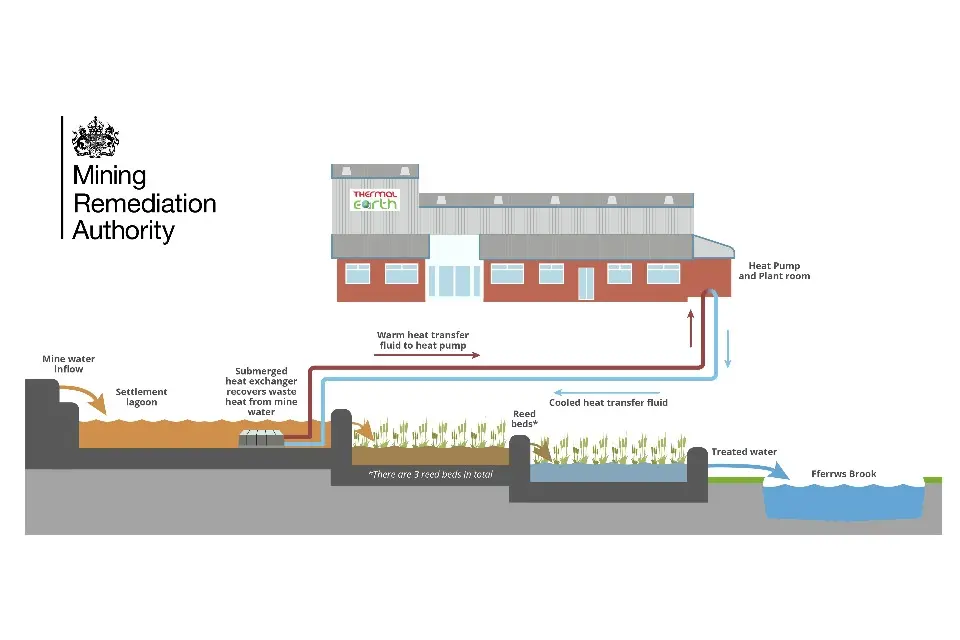

How Mine Water Heat Recovery Works

Heat pumps extract thermal energy from warm mine water and boost it to temperatures suitable for heating buildings.

Water naturally heats underground

Flooded mines are warmed by the Earth's constant subsurface temperature (12-14°C)

Heat is extracted via heat exchanger

Closed or open loop systems transfer thermal energy from the mine water

Heat pump boosts temperature

The heat pump raises the temperature to 45-55°C for space heating and hot water

Cooled water returns to mine

The water is returned to be naturally reheated, creating a sustainable cycle

How Mine Water Heat Recovery Works

Heat pumps extract thermal energy from warm mine water and boost it to temperatures suitable for heating buildings.

Water naturally heats underground

Flooded mines are warmed by the Earth's constant subsurface temperature (12-14°C)

Heat is extracted via heat exchanger

Closed or open loop systems transfer thermal energy from the mine water

Heat pump boosts temperature

The heat pump raises the temperature to 45-55°C for space heating and hot water

Cooled water returns to mine

The water is returned to be naturally reheated, creating a sustainable cycle

Thermal Earth Pioneering Mine Water Heat

We've developed Wales' first commercial mine water heat scheme at our Lindsay treatment facility in Ammanford—providing low-carbon heating to our own warehouse and offices, and demonstrating what's possible for the future.

Thermal Earth Pioneering Mine Water Heat

We've developed Wales' first commercial mine water heat scheme at our Lindsay treatment facility in Ammanford—providing low-carbon heating to our own warehouse and offices, and demonstrating what's possible for the future.

Open Loop vs Closed Loop Systems

Two approaches to extracting heat from mine water

Open Loop

Mine water is pumped to the surface, passed through a heat exchanger, then returned to the mine or discharged to a water source.

- Higher heat extraction rates

- Requires water discharge permit

- Best for large-scale schemes

- May require water treatment

Closed Loop

A sealed heat exchanger is submerged in the mine water. Clean water circulates in a secondary loop to the heat pump.

- No water extraction required

- Simpler permitting process

- Lower maintenance needs

- Ideal for smaller installations

Open Loop vs Closed Loop Systems

Two approaches to extracting heat from mine water

Open Loop

Mine water is pumped to the surface, passed through a heat exchanger, then returned to the mine or discharged to a water source.

- Higher heat extraction rates

- Requires water discharge permit

- Best for large-scale schemes

- May require water treatment

Closed Loop

A sealed heat exchanger is submerged in the mine water. Clean water circulates in a secondary loop to the heat pump.

- No water extraction required

- Simpler permitting process

- Lower maintenance needs

- Ideal for smaller installations

Funding Available for Heat Pump Projects

The Boiler Upgrade Scheme offers £7,500 towards heat pump installations. Commercial projects may qualify for additional funding through Welsh Government initiatives.

Explore Funding Options →Funding Available for Heat Pump Projects

The Boiler Upgrade Scheme offers £7,500 towards heat pump installations. Commercial projects may qualify for additional funding through Welsh Government initiatives.

Explore Funding Options →Interested in Mine Water Heat Recovery?

Whether you're a local authority, housing developer, or commercial property owner near former mining areas, we can assess the feasibility of a mine water heat scheme for your project.

Interested in Mine Water Heat Recovery?

Whether you're a local authority, housing developer, or commercial property owner near former mining areas, we can assess the feasibility of a mine water heat scheme for your project.

Frequently Asked Questions

Common questions about mine water heat recovery

Frequently Asked Questions

Common questions about mine water heat recovery

Demostrating What Is Possible!

By completing this demonstration system, we have successfully converted our facility away from liquefied petroleum gas, reducing dependence on fossil fuels and showcasing the possibilities of innovative renewable solutions.