There are plenty of options available for your home that can help save energy. Here are our tips and advice to help you save money and energy heating your home.

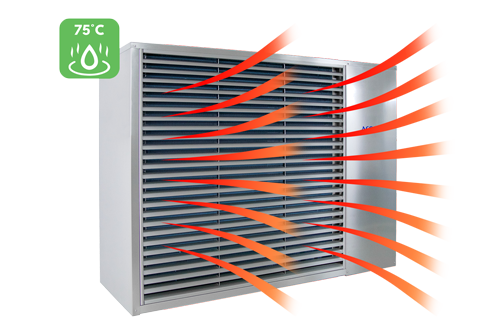

As a general, heat pumps in the UK are paired with wet heating systems filled with tap water and chemical inhibitor designed to prevent corrosion in the system.

However, there are some greener options to consider for those customers seeking a green heating system. These are com . . .

By announcing their target to cut carbon emissions to net zero by 2050 and mandating the end of fossil fuel heating systems in new homes from 2025, the UK is making big, bold moves for a cleaner, greener future.

Businesses are always striving to find the most cost-effective solution to reduce costs while still benefitting from efficiency, performance and for many, sustainability also plays a key role.

The government has set out its plan to incentivise people to install low-carbon heating systems such as heat pumps, which run on electricity and extract energy from the air or ground.

Maximise the potential of Solar Thermal technology by combining a Ground Source Heat Pump.

Building a new home or renovating an existing property? Find out more about passive cooling.

Installation of underfloor heating and a ground source heat pump system in a 7,000 sq. ft. cafe and play centre.

Learn more about using battery energy storage in the home and how it could save you money.

Learn more about district heating and how it can benefit communities.

Find out more about how heat pumps can be used for central heating in domestic and commercial buildings.

Learn more about heat pump efficiency including which heat pump is the most efficient and how efficiency is rated.

Waste water is an untapped resource for low-carbon, sustainable heating.

The new regulation comes into place on the 1st October 2021.

Not sure about the difference between single and three phase power supply and why it matters to your heat pump installation? Find out all you need to know in our blog.

Installation of two ground source heat pumps for an office and residential property.

Learn more about the process of drilling boreholes for the purpose of installing a ground source heat pump.

Learn more about the Green Heat Network Fund (GHNF), a UK government subsidy for low-carbon heat network projects.

Consulting giant EY suggests 10,000 heat pump installers will be required by 2025.

Mastertherm has just released the next generation WiFi touch screen control display packed with features for both end users and installers.

We've become a finalist for 'Public Building Energy Project of the Year' at the Energy Awards 2021.

Developing a ground source heating system for 170 sustainable homes in Wales.

How do heat pumps stack up against the UK's most common heating system?

Installation of 2x AQ45i Ground Source heat pumps with a combined output of 44kW.

Whether your property is off-grid or you're just considering alternatives, here are some potential options for heating a house without gas.

Learn more about how a ground source heat pump can be used for providing sustainable heating for both domestic and commercial swimming pools.

We've been appointed to the WPA & SWPA Decarbonisation & Energy Efficiency Framework (N8).

Find out the purpose of a buffer tank, average cost and if you need them for every heat pump installation.

Installation of a Lake Collector heat pump system for 2 residential properties in Carmarthenshire.

On the 18th November 2020, the UK Government unveiled a 10 point plan for a Green Industrial Revolution including a target of 600,000 heat pump installations a year.

Redevelopment of a 20th century school house into modern, hi-spec apartments.

Install of 6 heat pumps for the £1.8 million refit of Jubilee Pool in Penzance, Cornwall.

Find out the average cost of installing a domestic ground source heat pump in the UK.

Learn more about your options for effective home heating for properties based off the grid.

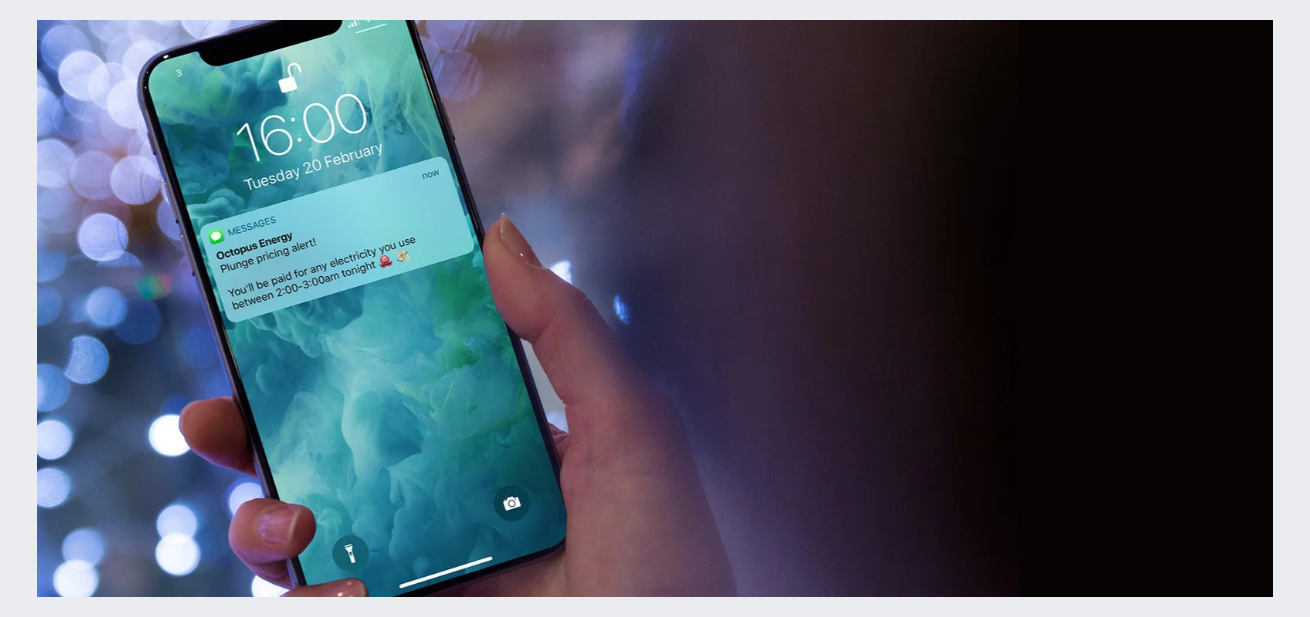

MasterTherm Heat Pumps can now be directly optimised for Agile Octopus using the Homely Energy system.

Ground Source Heat Pump Installation 10 x AQ17i installation

The difference between true heat pumps and heat pump like AC units.

Supply of 2 x MasterTherm Ground Source Heat Pump Units, 1 x 45kW AquaMaster and 1 x 8kW AquaMaster Inverter for indoor swimming pool.

The UK Government have announced an extension to the Domestic RHI to 31st March 2022

Supply & installation of MasterTherm 12kW AquaMaster Ground Source Heat Pump and Underfloor Heating.

Vertical or Horizontal Collector, how much space do you really need?

A fine example of the capabilities of MasterTherm Heat Pumps and the expertise that is available to the UK market in facilities that require process cooling and heat recovery

Thermal Earth announce a new addition to its MasterTherm GSHP range of products: the 1-5kW AQ17I

3 x MasterTherm AquaMaster Inverter - 66kW peak capacity providing heating and hot water.

2 x MasterTherm AquaMaster Inverter 22kW - 44kW total on Single Phase supply

Development of 40 Houses with a mix of Ground and Air Source Heat Pumps

MasterTherm EasyMaster Indoor Air Source Heat Pump - 25kW

Blending historical preservation with modern sustainability.

As the world grapples with climate change, the push for sustainable energy solutions has never been more critical. One technology gaining traction is the heat pump, which promises to revolutionize home heating and cooling.

Ffos Y Broga retrofit residential property to replace an existing oil heating system, consists of a single 18kW ACOND PRO R ASHP.

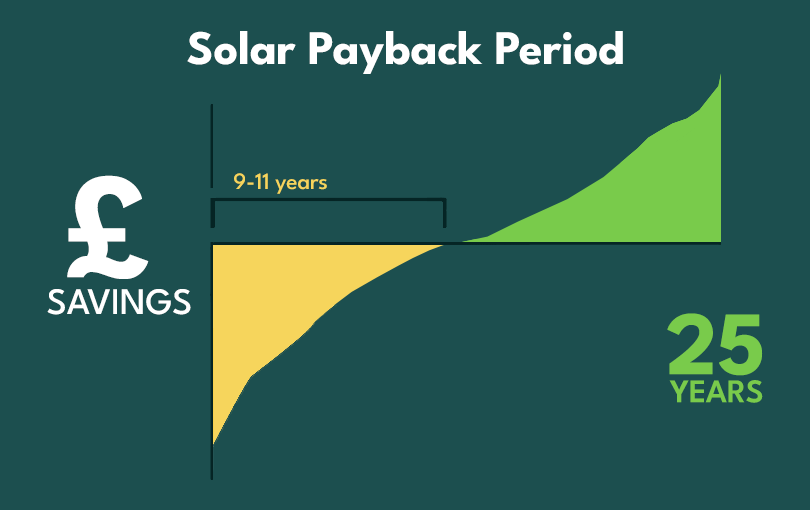

This blog post delves into the role of heat pumps, solar photovoltaic (PV) systems, batteries and smart home technology in empowering households to participate in the future energy system while achieving net zero emissions.

Say goodbye to fixed electricity rates and hello to dynamic savings. Learn how this groundbreaking tariff from Octopus Energy empowers homeowners to slash energy bills by leveraging real-time pricing.

With the increasing focus on sustainability and energy efficiency, heat pumps have emerged as a popular alternative for heating and cooling our homes and buildings. However, before diving into the installation process, it's crucial to understand the intricacies involved, includin . . .

A newly constructed school development integrates state-of-the-art heating technology with two MasterTherm BA60i units, ensuring reliable heating and hot water provision.

Let's Dive into SCOP and A+++ rated heat pumps and how they can save you money.

This project involves the installation of a state-of-the-art MasterTherm BA60I heat pump, which promises to enhance energy efficiency and provide superior heating comfort.

Eco-Heating Fit for Royalty - MasterTherm AQ90I at This Tudor Manor in Liverpool, which now enjoys efficient heating all year round.

This state-of-the-art heat pump is designed to provide efficient and sustainable heating solutions for your home.

In today’s world, where sustainability and ethical practices are more important than ever, MasterTherm stands out as a beacon of responsible innovation. Recognized by Ethical Consumer, MasterTherm has earned its place among the top eco-friendly heat pump brands, making significan . . .

Here we dive deep into the world of ground source heat pumps (GSHPs) and what they can do for your home comfort.

Energy prices in the UK are set to rise by about 10% from October 1, 2024. Find out how making the right choices now, could save you money in the future.

We are excited to announce the installation of the new MasterTherm BoxAir Inverter 5-17kW R290 Air Source Heat Pump (ASHP) for our valued client.

In this blog post, we'll delve into what exactly R290 refrigerant is and how it contributes to enhanced heat pump performance.

The Acond is a prime example of an Environmentally friendly and future-proof all round system.

Thermal Earth Ltd: Committed to a Net Zero Future. Supporting the plating of tree's and reducing cO2 emitions.

In our latest project, we successfully installed three MasterTherm AQ37 air source heat pumps, creating an efficient and sustainable heating solution for a main house and a barn.

A stunning state-of-the-art 26,000 ft2 new build family home featuring 4 x MasterTherm AQ45i systems, integrated with underfloor heating, and Solar PV.

In this blog post, we will explore the reasons behind the energy price hike, its connection to the UK's reliance on fossil fuels.

Thermal Earth Heat Pumps: Your Trusted Supplier of Ariston Heat Pumps

The ACOND purrs as quiet as a cat, ensuring your home remains a haven of peace and quiet.

While heat pumps offer low-maintenance heating, it remains crucial to schedule regular servicing to ensure their safe and efficient performance.

Exquisite new construction showcases opulent living and a commitment to energy conservation. Boasting Two ACOND PRO R Air Source Heat Pumps.

Discover the UK's shift towards low-carbon heating solutions amid climate change concerns. Join forward-thinking installers leading the eco-friendly revolution.

A newly constructed residential complex comprising of 44 one and two-bedroom flats spread across five floors, designed for an innovative Community Living scheme.

A state-of-the-art, custom-made system located on the River Thames is revolutionising heating, cooling, and hot water provision for the RNLI Waterloo Bridge lifeboat station.

Thirteen properties, including seven houses and six flats, boast cutting-edge sustainability features, anchored by a shared ground loop array and five boreholes reaching depths of up to 150 meters.

We're delighted to have been part of this recent project, providing year-round comfort for 170+ houses with MasterTherm AQ70 installations.

The Secretary of State for Energy Security and Net Zero has given permission for Ofgem to over-allocate vouchers by up to £50 million in this financial year, to a total of up to £200 million.

Heat pumps are becoming increasingly popular as a sustainable and efficient way to heat and cool homes. However, there are still many misconceptions about how they work and their effectiveness. Let’s debunk some of the most common myths about heat pumps.

This homeowner was tired of their outdated, noisy heating system that clashed with their home's décor. They sought a solution that combined efficiency, style, and sustainability.

© Thermal Earth Ltd 2025. All Rights Reserved.

Facebook

Facebook LinkedIn

LinkedIn Twitter

Twitter